Load Duration Factors

Load Duration Factor, or LDF, is based on the ability of wood to recover after a reasonable load has been applied for a given time. Wood is a stiff material but it is not completely rigid. Wood will flex under load, and once that load has been removed, the wood member will rebound or spring back to its original shape (if the load was not excessive or applied for too long). LDF is relevant in the case of regular service loads that are expected to act on a structure and that the member in consideration must resist without failure. LDF does not address loads that overstress a member to the point of breakage.

Some loads are expected to act on a structure for short periods of time, such as wind and seismic loads whose duration would normally be measurable in seconds. Other loads, such as snow, might last at least three months, depending on geography. Dead loads are permanent and they are expected to act on a structure for the life of that structure. Load Duration Factors allows us to increase the load carrying capacity of wood based on how long a load is expected to act on a structure--the shorter the period of time, the higher the allowed increase.

Load Duration Factors are applied to the capacity or resistance of the member, not to the loads on the member. Only those capacities or resistances that are related to the wood's ability to recover from a load are subject to LDF adjustments, i.e. moment and shear. Bearing capacity is not adjusted for LDF for IBC and it is adjusted for NBCC. Instantaneous deflection is also not affected by LDF because we are measuring how far the member flexes, not for how long. There is a deflection analysis type called Creep Analysis that checks long term deflection beyond instantaneous deflections due to heavy loads acting on a member for long periods of time. Our software does not analyze this type of deflection because North American building codes do not require creep analysis. However for Parallam® Plus, an approximation of long term deflection (creep) is included in the total load deflection result.

Load Duration Factors are tightly integrated into the load combinations used to load a member, i.e. if a load combination has both dead and wind loads then the load duration factor for this load combination will be the higher value defined by wind. Even though a load combination may have loads that are more permanent, by default the load combination will apply the LDF of the shortest acting load. The software will run through all the load combinations and their LDFs as required by the building codes and will pick the one that produces the highest stresses as the critical load combination for a particular design check.

The IBC allows designers to choose what load duration factor (CD) can be applied with a given load. The table below shows the LDF default values and the ranges our software allows.

| Default LDF | Range | Loading |

|---|---|---|

| CD = 0.90 | -- | Dead load only |

| CD = 1.00 | 0.90 - 1.00 | Floor and Heavy Snow Load |

| CD = 1.15 | 1.00 - 1.15 | Snow Load |

| CD = 1.25 | 1.00 - 1.25 | Roof Load, Construction Load |

| CD = 1.60 | 1.00 - 1.60 | Wind Load, Seismic Load |

If you choose an LDF that is too low then the software will automatically use the minimum value in the allowed range. If you choose an LDF that is too high then the software will automatically use the maximum value in the allowed range. It is your responsibility to choose the correct LDF for the problem at hand. Notice that the software defaults to the highest possible factor (which is liberal but correct most of the time). For example, if you are designing a structure for an area with heavy snow loads which might be in place for half a year, it would be reasonable to reduce your snow LDF to 1.00, Always consult your local building officials when in doubt.

How to change Load Duration Factors in ForteWEB

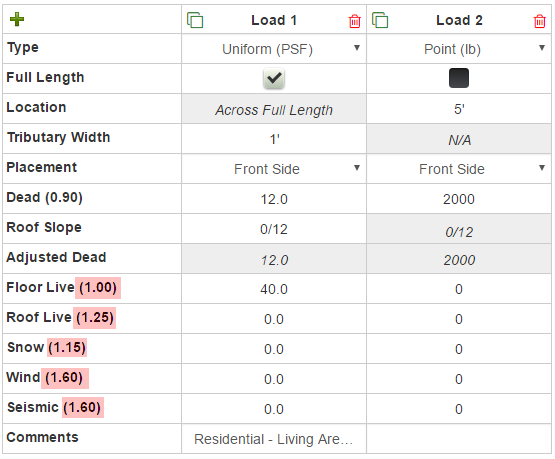

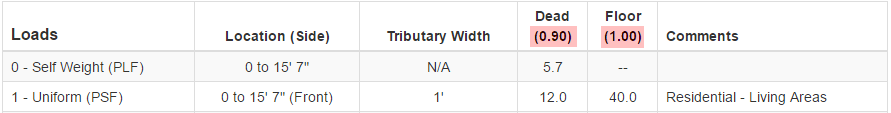

Load Duration Factors can be changed in the Job Settings tab and is only available under IBC. The values set here will display on both the Loads Tab and the Member Report.

Loads Tab:

Member Report:

The NBCC uses the load duration factor (Kd) concept but does not allow designers to pick and choose LDF values. The software will automatically assign the correct LDF to a given load combination as per the NBCC. The table below shows the load duration factors used for Canada.

| Duration of loading | Kd | Description |

|---|---|---|

| Short term | 1.15 | Duration of the loads is not expected to last more than 7 days continuously or cumulatively through the life of the structure, i.e. wind, earthquake, formwork, and impact loads. |

| Standard term | 1.00 | Duration of load exceeds that of short-tern loading, but is less than permanent loading, i.e. floor and snow loads. |

| Permanent | 0.65 | Member is subjected to load continuously, i.e. dead loads or dead loads plus live loads where the live loads are imposed on the structure as long as the dead loads. |

When a load combination has a dead load higher than the standard live load then the software will automatically adjust Kd based on a logarithmic equation but this recalculated value will not be less than 0.65 or exceed 1.00.